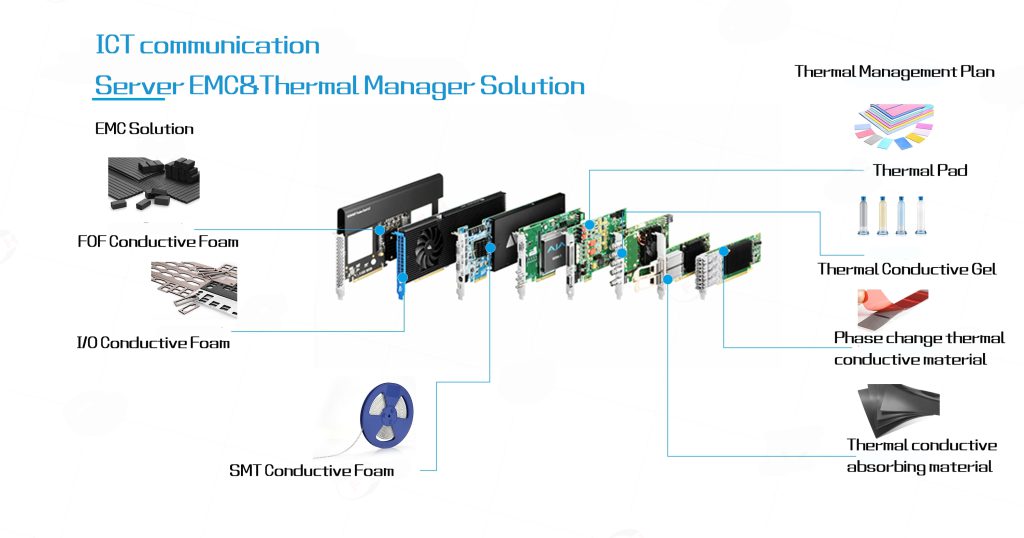

In the era of data centers and cloud computing, server power density and reliability are paramount. Every watt of power presents a significant thermal challenge, while high-frequency, high-speed computing environments demand stringent Electromagnetic Interference (EMI) control. A single material cannot solve all problems; a successful server design relies on a comprehensive suite of precision Thermal Interface Materials (TIMs) and Electromagnetic Compatibility (EMC) shielding solutions.

Here are the seven key materials essential for ensuring the stability of your next-generation servers:

I. The Core Thermal Matrix: Addressing Diverse Heat Sources & Structures

- Thermal Pads: The Workhorse of Cooling Systems

As the most versatile and reliable thermal interface material, thermal pads are ubiquitous in servers. They are widely applied between:- CPU/GPU bases and heat sinks: Filling macro imperfections to provide a durable, stable thermal path.

- Power Management ICs (PMICs): Efficiently dissipating heat from concentrated sources.

- Memory Modules: Providing necessary cooling for high-density DRAM.

- Chipsets and NVMe SSDs: Preventing performance throttling due to overheating.

- Advantages: Easy installation, excellent electrical insulation, high reliability, long-term stability, and no pump-out.

- Thermal Gel: The Ultimate Solution for Complex & Irregular Surfaces

In modern servers where space is extremely tight and component heights are uneven, thermal gel is the ideal choice:- Applications: When multiple chips of varying heights share a single large heatsink; for ASICs/FPGAs with exposed capacitors or irregular surfaces.

- Advantages: Extremely low interfacial thermal resistance, perfect conformity to any complex surface, maximizing the effective contact area, delivering performance akin to liquid metal while remaining electrically insulating.

- Phase Change Materials: Engineered for Peak CPU/GPU Performance

This is the advanced material for handling the highest power-density processors, such as high-end CPUs and GPUs.- How It Works: Solid at room temperature for easy handling and shipping. Upon reaching operational temperature (typically 45-60°C), it changes phase to a liquid, filling all microscopic voids like thermal grease, achieving the lowest possible interface thermal resistance.

- Advantages: Combines the easy handling of a pad with the ultra-high performance of thermal grease, making it the definitive choice for pursuing ultimate cooling.

- Carbon-Based Thermal Pads: Conquering Space Constraints

As server board integration increases, the compression space required for traditional pads becomes a luxury.- Applications: On-board chips (e.g., under BGA packages), ultra-thin server blades, and any application where the gap is less than 0.3mm.

- Advantages: Provides exceptional thermal conductivity at minimal thicknesses (as low as 0.1mm), coupled with excellent mechanical strength and gap-filling capability.

II. The EMC Guardians: Ensuring Signal Integrity & System Stability

Thermal management is not the only challenge. Electromagnetic radiation from high-speed signals must be effectively controlled.

- Thermal Absorbers: The Elegant “Dual-Function” Solution

This is a revolutionary material that simultaneously solves two critical problems: Heat Dissipation and EMI Suppression.- Applications:

- Covering Wi-Fi/BT modules and RF chips, absorbing specific frequency electromagnetic waves while dissipating heat to prevent signal crosstalk.

- Used inside server chassis to reduce overall EMI levels and assist with FCC/CE certification.

- Advantages: Two functions in one material, simplifying design, saving space, and perfect for highly integrated designs.

- Applications:

- FOF Conductive Foam: The Ideal Shielding for Chassis & Covers

FOF (Fabric-over-Foam) consists of a soft conductive foam core covered with a conductive fabric, creating a material that offers excellent shielding effectiveness and good compression recovery.- Applications: Primarily used on server chassis covers, drawer panels, and I/O brackets to fill gaps between metal parts, forming a continuous conductive ground and thus a complete “Faraday cage.”

- Advantages: Excellent surface contact conductivity, low compression force, long service life, and suitable for frequent access.

- I/O Conductive Foam & SMT Conductive Foam: Precision Strikes Against EMI Leakage

- I/O Conductive Foam: Specifically designed for various Input/Output ports (e.g., Ethernet, USB, HDMI). They are precision die-cut and installed between the port housing and the chassis to prevent electromagnetic energy from leaking through these apertures.

- SMT Conductive Foam: The pinnacle of automated production. This foam can be placed directly onto the PCB using Surface-Mount Technology (SMT), being soldered simultaneously with other components during the reflow process.

- Applications: Inside shields for localized chip shielding; on PCB edges for board-level shielding.

- Advantages: Enables full automation, drastically improving production efficiency while ensuring high consistency and reliability.

Conclusion: Synergistic Design is Key

In the demanding environment of a server, no material is an island. Thermal Pads, Gels, and Phase Change Materials work in concert to build efficient heat dissipation paths. Meanwhile, Thermal Absorbers, FOF, I/O, and SMT Conductive Foams collectively build a robust defense against electromagnetic interference.

Selecting a supplier that provides a complete product portfolio and deep application expertise is the foundation for ensuring your servers achieve the highest performance and reliability through all stages: design, testing, and mass production. We are committed to providing you with a full suite of solutions—from material selection and prototyping to production support—to help you build more stable and efficient next-generation data center infrastructure.