Modern laptop computers represent one of the most challenging environments for thermal management engineers. The continuous pursuit of thinner form factors and higher computing performance has created unprecedented thermal density issues. This article examines the comprehensive material solutions required for effective laptop thermal management.

Critical Thermal Challenges in Laptop Design

Key Heat Sources:

- High-performance CPUs and GPUs

- Power delivery circuits and voltage regulators

- Memory modules and storage devices

- Charging circuits and power management ICs

Design Constraints:

- Ultra-thin profiles with minimal z-height

- Limited airflow and restricted fan sizes

- Multiple heat-generating components in close proximity

- Aesthetic and ergonomic requirements

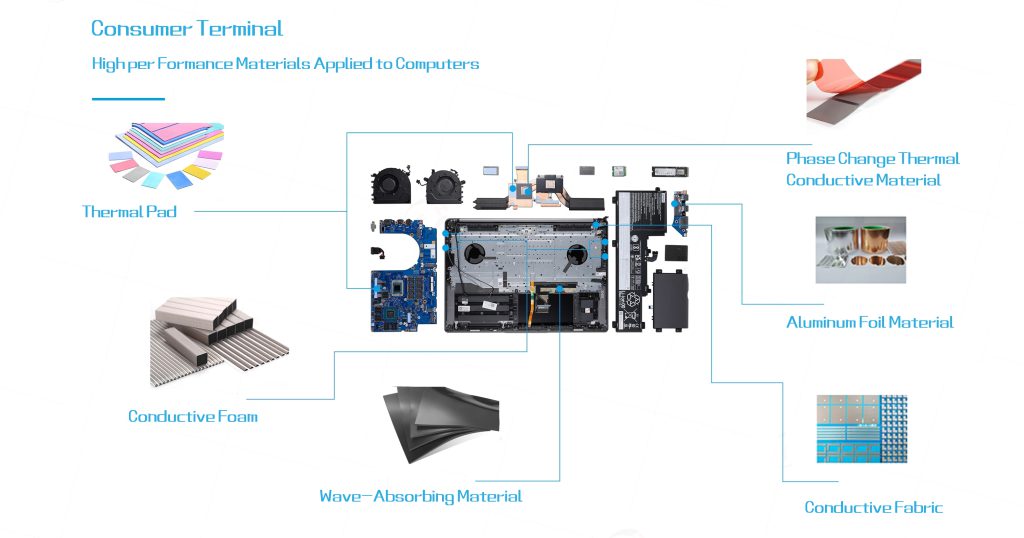

Comprehensive Material Solutions

1. Thermal Pads: Versatile Interface Material

Thermal pads serve as the workhorse for numerous applications throughout laptop assemblies:

Primary Applications:

- Memory chips and storage devices (NVMe SSDs)

- Power delivery components and voltage regulators

- Secondary heat sources requiring moderate cooling

Advantages:

- Electrical isolation properties

- Easy installation and rework capability

- Consistent performance across various thicknesses

- Cost-effective for multiple applications

2. Thermal Gel: Precision Thermal Interface

Thermal gel addresses the most challenging thermal interfaces in laptop computing:

Critical Applications:

- Between processors and heat pipes/heat spreaders

- High-power density components with irregular surfaces

- Applications requiring ultra-low thermal resistance

Performance Benefits:

- Perfect conformity to surface imperfections

- Maximum heat transfer efficiency

- Automated dispensing compatibility

- Excellent long-term stability

3. Phase Change Materials: Premium Processor Interface

These materials provide optimal performance for primary heat sources:

Implementation:

- CPU and GPU interfaces with heatsinks

- Applications requiring minimal bond line thickness

- Where factory-applied thermal solutions are specified

Technical Advantages:

- Automated application capability

- Consistent performance across thermal cycles

- Superior performance compared to traditional greases

4. Thermally Conductive Absorbers: Dual-Function Solutions

These advanced materials address both thermal and electromagnetic challenges:

Strategic Applications:

- Wireless communication modules (Wi-Fi, Bluetooth)

- High-speed interfaces and data ports

- Areas requiring simultaneous EMI suppression and heat dissipation

5. EMC Shielding Materials: Signal Integrity Management

Conductive Foam:

- Grounding applications between shields and chassis

- Gasketing for display interfaces and I/O ports

- Vibration damping with electrical conductivity

Aluminum Foil Materials:

- Cable shielding and wrap-around protection

- Localized shield cans and enclosures

- Cost-effective EMI containment

Conductive Fabric:

- Shielded window applications

- Flexible gasketing solutions

- Wrap-around cable shielding

Implementation Strategy for Laptop Design

Tiered Thermal Approach:

- Phase change materials or thermal gel for processors

- Thermal pads for secondary heat sources

- Thermally conductive absorbers for RF/wireless components

EMI Control Framework:

- Conductive foam for mechanical grounding interfaces

- Aluminum foil for cable and localized shielding

- Conductive fabric for complex geometric requirements

Performance Optimization

Thermal Management:

- Hierarchical material selection based on power density

- Optimized interface thickness for each application

- Balanced approach considering cost and performance

EMI Control:

- Comprehensive shielding strategy using complementary materials

- Proper grounding implementation throughout assembly

- Signal integrity maintenance through effective isolation

Conclusion

Successful laptop thermal management requires an integrated approach combining multiple advanced materials. The strategic implementation of thermal interface materials alongside EMI shielding solutions enables manufacturers to achieve the delicate balance between performance, reliability, and form factor requirements.

As laptop technology continues to evolve toward higher performance in thinner packages, the sophisticated application of these material solutions becomes increasingly critical. Manufacturers who master the strategic deployment of these advanced materials will lead the industry in delivering computers that meet both performance expectations and user experience demands.