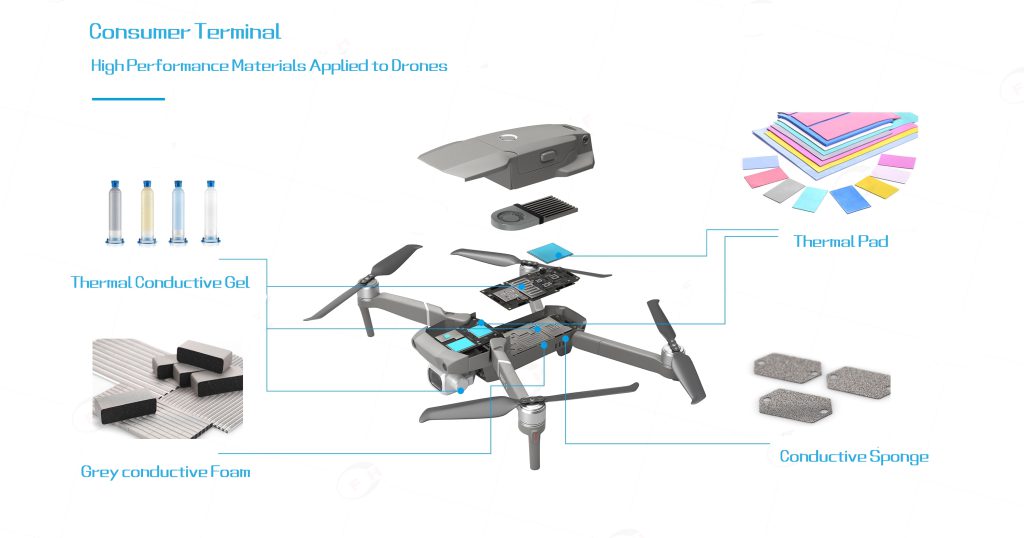

The rapid evolution of drone technology has created unprecedented thermal management and electromagnetic compatibility challenges. This article examines the strategic application of thermal gel, thermal pads, and conductive foam in addressing these critical requirements for modern unmanned aerial systems.

Thermal and Operational Challenges in Drones

Primary Heat Sources:

- Flight controllers and main processing units

- Motor controllers and electronic speed controllers (ESCs)

- High-resolution camera systems and gimbals

- Communication modules (4G/5G, GPS, RF transmitters)

- Battery management systems and power distribution boards

Critical Design Constraints:

- Extreme weight limitations affecting heat sink size

- Exposure to varying environmental conditions (-20°C to 60°C)

- Vibration and shock during flight operations

- Limited space for thermal management solutions

- Stringent EMI requirements for reliable communications

Material Solutions for Drone Applications

1. Thermal Gel: Precision Thermal Interface for Critical Components

Strategic Applications:

- Between main processor and heat spreader in flight controllers

- High-power motor controllers and ESC modules

- Image processing units in camera systems

- Areas requiring maximum thermal performance in minimal space

Performance Advantages:

- Excellent surface wetting for minimal thermal resistance

- Superior performance under continuous vibration conditions

- Long-term stability across temperature extremes

- Maintains integrity during rapid temperature cycling

2. Thermal Pads: Versatile Thermal Management Solution

Implementation Areas:

- Power management ICs and voltage regulators

- Memory modules and storage devices

- RF modules and communication interfaces

- Battery monitoring circuits and charging systems

Key Benefits:

- Electrical isolation for sensitive components

- Easy installation and maintenance accessibility

- Good compressibility for varying tolerance stacks

- Cost-effective solution for multiple applications

3. Conductive Foam: EMI Shielding and Grounding Solution

Critical Applications:

- Shielding for camera modules and sensitive sensors

- Grounding between PCB and drone frame

- EMI protection for wireless communication units

- Vibration damping for delicate electronic components

Technical Advantages:

- Excellent compression recovery for repeated access

- Reliable electrical contact under vibration

- Lightweight solution for weight-critical applications

- Environmental sealing capabilities

Integrated Implementation Strategy

Thermal Management Approach:

- Thermal gel for high-heat flux components (processors, motor controllers)

- Thermal pads for moderate heat-generating components and power circuits

- Strategic material selection based on specific thermal requirements

EMI Control Framework:

- Conductive foam for module-level shielding and frame grounding

- Comprehensive EMI strategy for sensitive flight control systems

- Vibration damping integration with EMI protection

Performance Optimization

Thermal Performance Considerations:

- Weight-optimized thermal solution design

- Performance maintenance under varying atmospheric conditions

- Efficient heat transfer from component to external environment

- Reliability under rapid temperature changes

EMI and Operational Reliability:

- Stable shielding performance during flight maneuvers

- Vibration-resistant grounding solutions

- Lightweight EMI protection maintaining flight efficiency

- Environmental protection for outdoor operations

Environmental and Reliability Factors

Operational Conditions:

- Performance maintenance in humid and dusty environments

- UV resistance for extended outdoor exposure

- Thermal cycling endurance from ground to operating altitudes

- Vibration resistance from motor and propeller operations

Quality and Reliability:

- Consistent performance under rapid pressure changes

- Material stability across operational temperature ranges

- Long-term reliability with minimal maintenance requirements

- Compatibility with automated manufacturing processes

Conclusion

The strategic implementation of thermal gel, thermal pads, and conductive foam enables drone manufacturers to overcome the unique challenges of UAV thermal management and electromagnetic compatibility. Thermal gel provides superior interface performance for critical heat-generating components, while thermal pads offer versatile solutions for broader application needs. Conductive foam delivers essential EMI protection and reliable grounding in challenging operational environments.

As drone technology advances with increased processing capabilities, higher-resolution imaging systems, and more sophisticated communication requirements, the importance of these material solutions continues to grow. Manufacturers who effectively leverage these advanced materials will produce drones that excel in reliability, performance, and operational capability, meeting the evolving demands of commercial, industrial, and consumer applications.

The future of drone innovation will increasingly depend on these thermal management and EMI solutions to ensure reliable operation in diverse environmental conditions while maintaining the weight and size constraints essential for optimal flight performance.