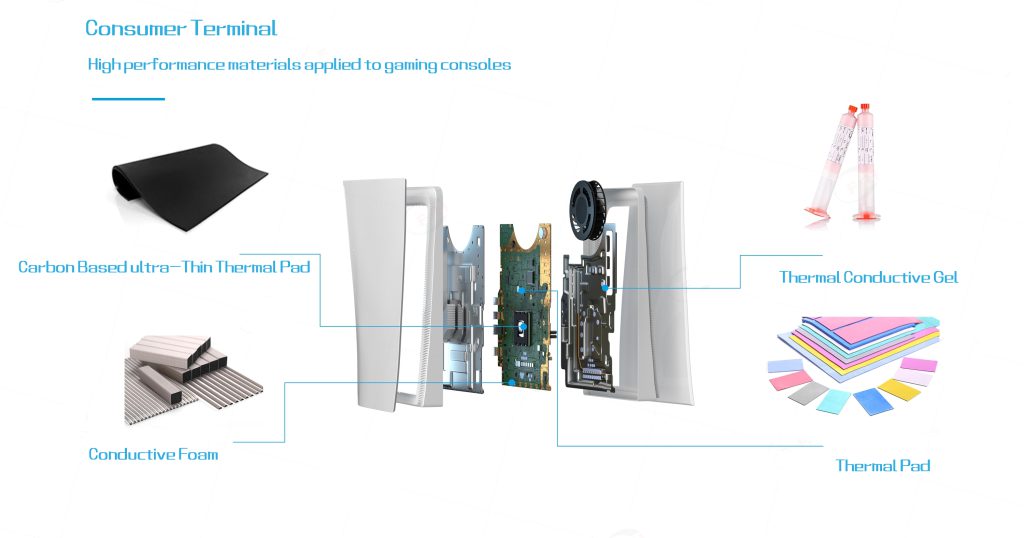

Modern gaming consoles represent the pinnacle of consumer electronics thermal management challenges, combining high-performance computing components with aesthetically driven form factors. This comprehensive analysis examines the strategic application of thermal gel, thermal pads, carbon-based thermal pads, and conductive foam in addressing the unique requirements of gaming console design.

Thermal and Technical Challenges in Gaming Consoles

Primary Heat Generation Sources:

- Central processing units (CPUs) and graphics processing units (GPUs) in System-on-Chip (SoC) configurations

- GDDR6X and future memory technologies with significant thermal output

- Power delivery systems and voltage regulation modules (VRMs)

- Solid-state drive (SSD) controllers and NAND flash arrays

- Optical drive systems and audio processing units

Critical Design Limitations:

- Acoustically constrained thermal solutions requiring minimal fan noise

- Aesthetically driven industrial design limiting ventilation opportunities

- Consumer safety requirements maintaining external surface temperatures

- Cost-sensitive manufacturing despite high-performance requirements

- Long product lifecycle expectations (5-7 years) with consistent performance

Advanced Material Solutions for Gaming Consoles

1. Thermal Gel: High-Performance Interface Solution

Strategic Implementation Areas:

Primary SoC Interface:

- Between main processor die and heat spreader base

- Applications requiring ultra-low thermal resistance (0.1°C-cm²/W or less)

- High-power density areas exceeding 15W/cm²

Memory and Power Delivery Cooling:

- GDDR6/6X memory modules on primary graphics board

- Multi-phase VRM assemblies with direct heat pipe contact

- SSD controller chips in next-generation storage systems

Technical Performance Advantages:

- Exceptional thermal conductivity ranging from 3.0 to 8.0 W/m·K

- Minimal bond line thickness achievement through perfect surface conformity

- Long-term stability maintaining performance through thermal cycling

- Zero pump-out characteristics ensuring consistent interface quality

- Automated dispensing compatibility for high-volume manufacturing

2. Standard Thermal Pads: Versatile Thermal Management

Application Spectrum:

Secondary Component Cooling:

- Southbridge and auxiliary processor interfaces

- Network interface controllers and audio processing chips

- USB controller hubs and interface management ICs

Power System Thermal Management:

- Power supply unit component interfaces

- Voltage regulation circuits with moderate thermal requirements

- Board-level power distribution components

Operational Benefits:

- Broad thermal conductivity range (1.5 to 6.0 W/m·K) suiting various needs

- Excellent dielectric strength ensuring electrical isolation

- Compressibility accommodating manufacturing tolerances

- Cost-effective solutions for multiple moderate-heat applications

3. Carbon-Based Thermal Pads: Premium Performance Solutions

Critical Implementation Areas:

Space-Constrained High-Performance Applications:

- Between memory chips and secondary heat spreaders

- Ultra-thin profile requirements behind main circuit boards

- Applications requiring maximum thermal performance in minimal z-height

Advanced Thermal Management Scenarios:

- Direct interface with vapor chamber systems

- High-compression modulus applications

- Environments requiring exceptional thermal anisotropy

Performance Characteristics:

- Superior thermal conductivity exceeding 15 W/m·K in some formulations

- Minimal thickness capabilities down to 0.25mm with high performance

- Enhanced mechanical properties for repeated thermal cycling

- Electrically conductive or insulating variants for specific applications

4. Conductive Foam: Comprehensive EMI Management

Strategic Shielding Applications:

Critical System Shielding:

- Main SoC compartment EMI containment

- Memory subsystem electromagnetic isolation

- Power delivery network RF interference suppression

Interface and Connector Management:

- HDMI 2.1 and display port interface shielding

- USB-C and high-speed data port EMI control

- Wireless module (Wi-Fi 6E, Bluetooth) containment

Performance Advantages:

- Consistent surface contact conductivity maintaining below 0.1Ω resistance

- Compression set resistance ensuring long-term shielding effectiveness

- Vibration damping protecting solder joints during transportation

- Environmental sealing capabilities against dust and particulate ingress

Integrated Implementation Methodology

Thermal Solution Architecture:

- Hierarchical approach matching material performance to component requirements

- Thermal gel for primary heat sources (SoC, memory, VRMs)

- Carbon-based pads for space-constrained high-performance areas

- Standard thermal pads for secondary thermal management needs

EMI Control Framework:

- Conductive foam creating compartmentalized shielding zones

- Strategic material placement addressing specific frequency ranges

- Comprehensive grounding strategy utilizing console chassis

Performance Validation and Reliability

Thermal Performance Metrics:

- SoC junction temperature maintenance below 85°C under sustained load

- Memory temperature control within manufacturer specifications

- External casing temperatures complying with safety standards

- Acoustic profiles meeting consumer expectations

EMI Compliance Requirements:

- FCC and international EMI/EMC standards compliance

- Wireless coexistence ensuring uninterrupted connectivity

- Signal integrity maintenance for high-speed interfaces

Long-Term Reliability:

- Performance maintenance through 10,000+ thermal cycles

- Material stability across 7-year product lifecycle

- Vibration and shock resistance exceeding transportation requirements

Manufacturing and Quality Assurance

Production Integration:

- Automated thermal gel dispensing with precision volume control

- Die-cut thermal pads and conductive foam for consistent placement

- Vision system verification ensuring proper material application

- Rework processes maintaining quality standards

Quality Control Protocols:

- Incoming material certification for thermal and electrical properties

- In-process monitoring of application parameters

- End-of-line thermal performance validation

- Accelerated life testing simulating years of operation

Conclusion

The sophisticated integration of thermal gel, thermal pads, carbon-based thermal pads, and conductive foam enables gaming console manufacturers to achieve unprecedented levels of performance while meeting stringent aesthetic, acoustic, and reliability requirements. Thermal gel provides the foundation for managing extreme heat fluxes from advanced processors, while carbon-based pads address space-constrained high-performance applications. Standard thermal pads deliver cost-effective solutions for broader thermal management needs, and conductive foam ensures comprehensive EMI control in electrically noisy environments.

As gaming consoles evolve toward higher computational densities and more compact form factors, these advanced material solutions will become increasingly critical to product success. Manufacturers who master the strategic deployment and integration of these materials will lead the industry in delivering consoles that excel in performance, reliability, and user experience, ultimately defining the next generation of interactive entertainment systems.