Photovoltaic inverters represent the critical heart of solar energy systems, converting DC power from solar panels into grid-compatible AC power. As the demand for higher efficiency and power density continues to grow, effective thermal management has become paramount for ensuring reliability, longevity, and optimal performance. This comprehensive analysis examines the strategic application of thermal pads and thermal gel in addressing the unique thermal challenges of PV inverters.

Thermal Challenges in PV Inverters

Primary Heat Generation Sources:

- IGBT/MOSFET power switching devices

- Diode rectifiers and freewheeling components

- DC-AC conversion circuits and power transformers

- Maximum Power Point Tracking (MPPT) controllers

- Grid-tie interface and synchronization circuits

- Filter components and electromagnetic compatibility circuits

Critical Operating Conditions:

- Continuous outdoor operation with solar exposure

- Wide ambient temperature ranges (-25°C to 60°C+)

- 24/7 operation with varying load conditions

- High humidity, dust, and environmental contaminants

- 20+ year operational lifetime requirements

Performance Implications:

- Efficiency reduction with temperature increase (0.1-0.5% per °C)

- Component degradation and reduced lifespan

- Increased failure rates in power semiconductors

- Output power derating at elevated temperatures

Material Properties and Selection Criteria

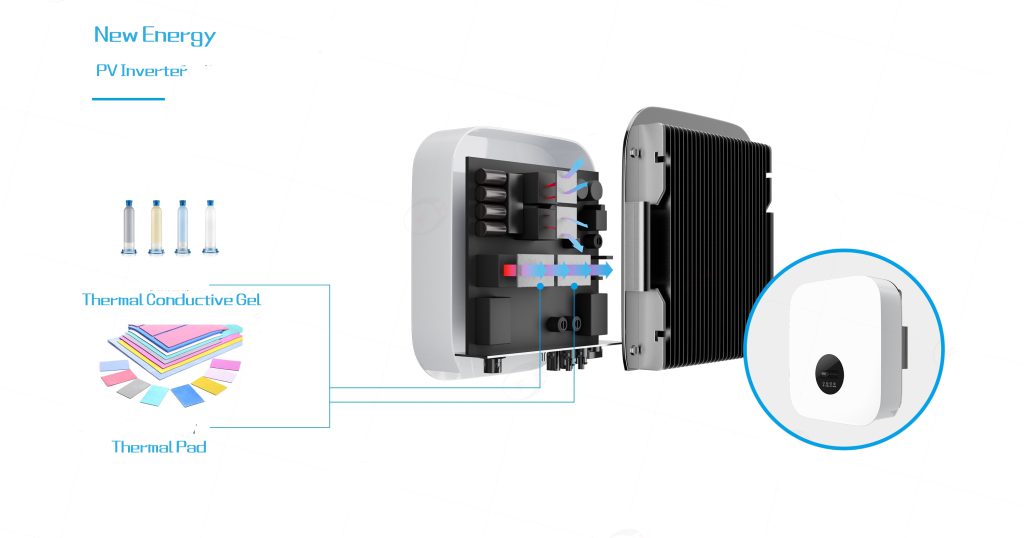

Thermal Pads: Characteristics and Advantages

Material Properties:

- Thermal conductivity range: 1.5 to 8.0 W/m·K

- Thickness options: 0.5mm to 5.0mm

- Compression range: 15-30% of original thickness

- Dielectric strength: 5-15 kV/mm

- Temperature resistance: -45°C to 200°C

- UL94 V-0 flame retardant grades available

Performance Benefits:

- Excellent gap-filling capability for irregular surfaces

- Electrical isolation properties

- Easy installation and reworkability

- Long-term stability without curing required

- Vibration and shock absorption

Thermal Gel: Advanced Interface Solution

Material Characteristics:

- Thermal conductivity: 2.0 to 6.0 W/m·K

- Low thermal resistance: <0.1°C-cm²/W

- Curing types: non-curing and curing formulations

- Application thickness: 0.1mm to 2.0mm

- Service temperature: -45°C to 180°C

- Dispensability for automated application

Technical Advantages:

- Superior surface wetting and conformity

- Minimal bond line thickness capability

- Excellent performance under thermal cycling

- Automated application compatibility

- High reliability in vibration environments

Strategic Applications in PV Inverters

Power Semiconductor Cooling:

IGBT/MOSFET Modules:

- Thermal gel for direct die-attach heat sink interfaces

- Thermal pads for baseplate to heat sink interfaces

- Multi-level thermal interface strategies

- High-power density (>100W/cm²) applications

Diode and Rectifier Assemblies:

- Thermal pads for press-fit packages

- Gel applications for stud-type devices

- Mixed technology thermal solutions

Control and Monitoring Circuits:

MPPT Controller Components:

- Thermal pads for controller ICs and supporting circuitry

- Gel applications for high-density control boards

- Mixed material strategies for optimal performance

Gate Driver Circuits:

- Thermal interface for driver ICs

- Isolation and thermal management integration

- Reliability-focused material selection

Auxiliary System Thermal Management:

DC-DC Converter Sections:

- Transformer and inductor thermal interfaces

- Switching device thermal management

- Complete power stage thermal solutions

Filter and EMC Components:

- Inductor core thermal coupling

- Resistor and capacitor thermal management

- System-level thermal optimization

Design Implementation Strategies

High-Power Central Inverters:

- Multi-level thermal interface architecture

- Thermal gel for primary power devices

- Thermal pads for secondary components and structural interfaces

- Automated application processes for manufacturing efficiency

String and Microinverters:

- Space-optimized thermal solutions

- Cost-performance balanced material selection

- Reliability-focused design approaches

- Environmental protection considerations

Reliability and Performance Validation

Thermal Performance Testing:

- Interface thermal resistance measurement

- System-level thermal impedance characterization

- Temperature rise validation under load cycling

- Heat flux density capacity verification

Environmental Reliability:

- Thermal cycling tests (-40°C to 125°C)

- Humidity and temperature bias testing

- Vibration and mechanical shock resistance

- Long-term aging studies

Safety and Compliance:

- UL and IEC standard compliance

- Flame resistance verification

- Electrical isolation testing

- Material compatibility validation

Case Studies and Performance Data

3MW Central Inverter Application:

- Thermal gel on IGBT modules: 15°C junction temperature reduction

- Thermal pads on support components: 25% improvement in temperature uniformity

- System efficiency improvement: 0.3% at full load

- Projected lifespan increase: 3 years

Commercial String Inverter Implementation:

- Hybrid thermal interface approach

- 20% reduction in heat sink size and cost

- Maintenance-free operation over 5-year period

- Consistent performance across environmental conditions

Future Trends and Developments

Material Technology Advancements:

- Higher conductivity formulations (10+ W/m·K)

- Phase change material integration

- Graphene and carbon nanotube enhancements

- Environmentally sustainable materials

Application Innovations:

- Digital twin integration for thermal optimization

- Smart thermal interface materials

- Automated quality control systems

- Integrated thermal and EMC solutions

Industry Evolution:

- Standardized thermal performance metrics

- Advanced predictive maintenance capabilities

- Improved reliability modeling

- Cost-performance optimization methodologies

Conclusion

The strategic implementation of thermal pads and thermal gel in PV inverters enables manufacturers to achieve the critical balance between performance, reliability, and cost-effectiveness. Thermal gel provides superior thermal interface performance for high-power density applications, while thermal pads offer versatile solutions for broader thermal management needs.

As PV inverters continue to evolve toward higher efficiencies, increased power densities, and more demanding environmental requirements, the importance of advanced thermal interface materials will only grow. Manufacturers who master the selection, application, and integration of these thermal management solutions will lead the industry in delivering inverters that meet the evolving demands of the global solar energy market.

The future success of PV inverter technology will increasingly depend on these thermal management solutions to ensure reliable operation, maximize energy harvest, and support the worldwide transition to sustainable energy systems. Through continued innovation and strategic material application, the solar industry can overcome thermal challenges and accelerate the adoption of clean energy technologies worldwide.