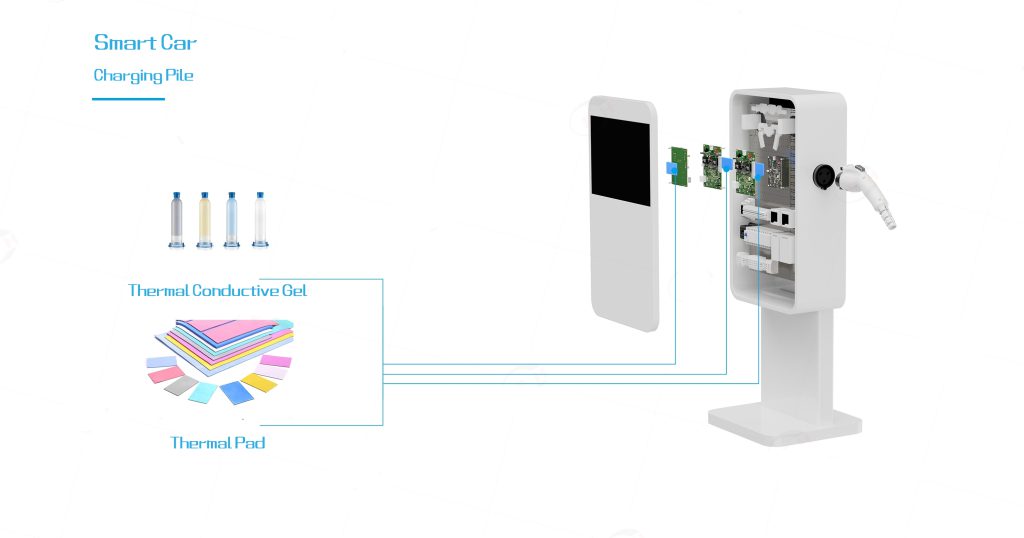

The rapid global adoption of electric vehicles has positioned charging infrastructure as a critical component in the transportation electrification ecosystem. As charging technology evolves toward higher power levels (350kW+) and faster charging times, effective thermal management has become paramount for ensuring safety, reliability, and optimal performance. This comprehensive analysis examines the strategic application of thermal pads and thermal gel in addressing the unique thermal challenges of EV charging stations.

Thermal Challenges in EV Charging Stations

Primary Heat Generation Sources:

- Power conversion modules (AC-DC and DC-DC converters)

- High-power semiconductor devices (SiC MOSFETs, IGBTs)

- DC contactors and power distribution components

- Liquid cooling systems and heat exchangers

- Control electronics and communication modules

- Payment systems and user interface components

Critical Operating Conditions:

- 24/7 continuous operation in varying climates

- Ambient temperature ranges from -30°C to 50°C

- High humidity, rain, snow, and ice exposure

- Dust, pollution, and environmental contaminants

- Vandalism and mechanical impact risks

- 10+ year operational lifetime requirements

Performance and Safety Implications:

- Efficiency reduction with temperature increase

- Component degradation and reduced lifespan

- Safety hazards from overheated components

- Charging speed reduction due to thermal throttling

- Increased maintenance costs and downtime

Material Properties and Selection Criteria

Thermal Pads: Versatile Interface Solution

Key Material Properties:

- Thermal conductivity: 2.0 to 8.0 W/m·K

- Thickness options: 0.5mm to 10.0mm

- Compression deflection: 10-35%

- Dielectric strength: 5-20 kV/mm

- Temperature range: -45°C to 200°C

- Flame retardancy: UL94 V-0 compliance

- Environmental resistance: UV, ozone, moisture

Performance Advantages:

- Excellent gap-filling for irregular surfaces

- Electrical isolation for high-voltage components

- Vibration damping and shock absorption

- Easy installation and maintenance

- Long-term stability without curing

Thermal Gel: High-Performance Interface Material

Material Characteristics:

- Thermal conductivity: 3.0 to 6.0 W/m·K

- Thermal resistance: <0.08°C-cm²/W

- Application methods: dispensing, stenciling

- Service temperature: -45°C to 180°C

- Curing options: non-curing and thermal curing

- Adhesion properties: minimal to moderate

Technical Benefits:

- Superior surface conformity and wetting

- Minimal bond line thickness capability

- Excellent performance under thermal cycling

- Automated application compatibility

- High reliability in vibration environments

Strategic Applications in Charging Stations

Power Conversion Systems:

DC Fast Charger Power Modules:

- Thermal gel for direct semiconductor die attachment

- Thermal pads for module baseplate to heat sink interfaces

- Multi-level thermal management strategies

- High-current density applications (200A+)

AC-DC Rectification Stages:

- Thermal interface for rectifier bridges

- Heat spreader attachment solutions

- Mixed technology thermal approaches

Control and Safety Systems:

Controller and Monitoring Circuits:

- Thermal pads for control board components

- Gel applications for high-density processing units

- Communication module thermal management

Safety and Protection Devices:

- DC contactor thermal interfaces

- Fuse and circuit breaker thermal management

- Emergency stop circuitry cooling

Auxiliary System Thermal Management:

Liquid Cooling Components:

- Heat exchanger thermal interfaces

- Pump and valve thermal management

- Coolant distribution system thermal optimization

User Interface and Payment Systems:

- Display driver thermal management

- Payment terminal component cooling

- Communication antenna thermal interfaces

Design Implementation Strategies

DC Fast Charger Systems:

- Multi-level thermal interface architecture

- Thermal gel for high-power semiconductor devices

- Thermal pads for structural and auxiliary interfaces

- Automated manufacturing processes

AC Level 2 Chargers:

- Cost-optimized thermal solutions

- Reliability-focused material selection

- Environmental protection considerations

- Maintenance-friendly designs

Reliability and Performance Validation

Thermal Performance Testing:

- Interface thermal resistance characterization

- System-level thermal impedance mapping

- Temperature rise validation under load cycling

- Heat flux density capacity verification

Environmental Reliability:

- Extended thermal cycling tests (-40°C to 125°C)

- Humidity and temperature bias testing

- Vibration and mechanical shock validation

- Long-term operational aging studies

Safety and Compliance:

- International standard compliance (IEC, UL, CE)

- Flame resistance verification

- Electrical isolation testing

- Material compatibility validation

Case Studies and Performance Data

350kW Ultra-Fast Charger Implementation:

- Thermal gel on SiC MOSFETs: 20°C junction temperature reduction

- Thermal pads on support components: 30% improvement in thermal uniformity

- System efficiency improvement: 0.4% at maximum load

- Projected lifespan increase: 4 years

Commercial AC Charger Deployment:

- Hybrid thermal interface approach

- 25% reduction in cooling system complexity

- Maintenance-free operation over 3-year period

- Consistent performance across environmental conditions

Future Trends and Developments

Material Technology Advancements:

- Higher conductivity formulations (12+ W/m·K)

- Phase change material integration

- Graphene-enhanced composite materials

- Sustainable and recyclable material options

Application Innovations:

- Digital thermal management systems

- Smart thermal interface materials

- Automated quality assurance systems

- Integrated thermal and safety solutions

Industry Evolution:

- Standardized thermal performance requirements

- Advanced predictive maintenance capabilities

- Improved reliability modeling techniques

- Global safety standard harmonization

Conclusion

The strategic implementation of thermal pads and thermal gel in EV charging stations enables manufacturers to achieve critical balance between performance, reliability, and safety requirements. Thermal gel provides superior thermal interface performance for high-power density applications, while thermal pads offer versatile solutions for broader thermal management needs.

As charging technology continues to advance toward higher power levels, increased reliability requirements, and more demanding environmental conditions, the importance of advanced thermal interface materials will only increase. Manufacturers who master the selection, application, and integration of these thermal management solutions will lead the industry in delivering charging infrastructure that meets the evolving demands of the global electric vehicle market.

The future success of EV charging infrastructure will increasingly depend on these thermal management solutions to ensure safe operation, maximize efficiency, and support the worldwide transition to electric transportation. Through continued innovation and strategic material application, the charging industry can overcome thermal challenges and accelerate the adoption of electric mobility worldwide.