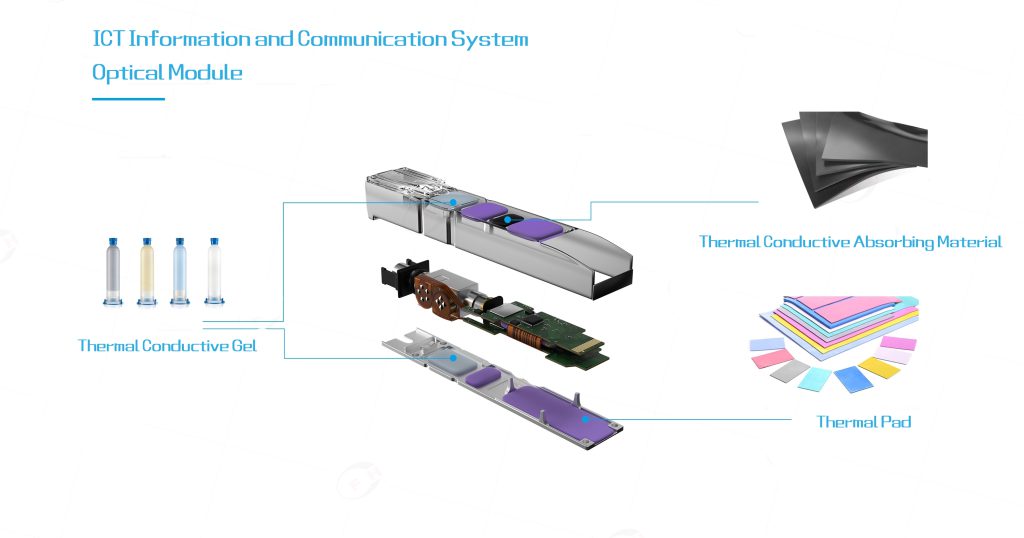

Thermal Management Solutions for Optical Modules: The Synergistic Application of Thermal Pads, Thermal Gel, and Thermally Conductive Absorbers

With the rapid development of 5G, data centers, and cloud computing technologies, optical modules, as the core components of information transmission, are evolving toward higher speeds, miniaturization, and higher integration. This trend has significantly increased the power density of optical modules, making heat dissipation and electromagnetic interference (EMI) critical challenges. Effective thermal management and EMI design have become key to ensuring the long-term stable operation of optical modules. This article focuses on the comprehensive application of thermal pads, thermal gel, and thermally conductive absorbers in optical modules.

1. Thermal Challenges in Optical Modules

Optical modules integrate high-performance components such as laser drivers, modulators, photodetectors, and DSP chips, which generate significant heat during operation. If this heat is not dissipated in a timely manner, it can lead to the following issues:

- Wavelength drift of the laser, affecting transmission performance;

- Reduced component lifespan;

- Degraded signal integrity and increased bit error rates.

Additionally, the rapid switching of high-frequency signals can cause electromagnetic interference, impacting the overall stability of the optical module.

2. Application of Key Materials in Optical Modules

2.1 Thermal Pads: The Versatile Workhorse for Heat Dissipation

Thermal pads are widely used in multiple heat-generating areas of optical modules due to their ease of installation, excellent electrical insulation, and high reliability:

- Between the main control chip and the housing: Filling gaps between the chip surface and the metal housing to create an efficient heat conduction path;

- Power management chips: Suitable for areas with relatively flat structures and moderate gaps, providing stable thermal support;

- Under local shielding covers: Offering both thermal conductivity and electrical insulation to prevent short circuits.

Thermal pads are particularly suitable for applications where extreme compression space is not required and long-term stable operation is critical.

2.2 Thermal Gel: Addressing Complex Structures and Tiny Gaps

As optical modules continue to shrink in size, height variations and structural complexities of internal components make it difficult for traditional pads to achieve perfect filling. Thermal gel has become the ideal solution for such challenges:

- Multiple-height chips sharing a heatsink: The gel conforms to irregular surfaces, ensuring optimal contact between chips of varying heights and the heatsink;

- Around optical components: Suitable for areas with exposed solder points or irregularly shaped components, enabling full-coverage thermal conduction;

- Ultra-thin optical modules: In spaces with gaps smaller than 0.3mm, the gel forms an ultra-low thermal resistance interface layer.

The advantage of thermal gel lies in its flowability and conformability, which maximize the effective contact area and achieve thermal performance comparable to phase change materials.

2.3 Thermally Conductive Absorbers: Dual-Function Materials for Heat Dissipation and EMI Suppression

In high-frequency optical modules, electromagnetic interference has become a critical concern. Thermally conductive absorbers innovatively combine thermal management and electromagnetic wave absorption functionalities:

- Above RF chips and high-speed interfaces: Dissipating heat while effectively absorbing electromagnetic radiation in specific frequency bands, preventing signal crosstalk;

- Inside the optical module housing: Attached to the metal housing, they serve as part of the thermal path while suppressing cavity resonance and reducing overall EMI levels;

- Near connectors: Isolating high-speed signal ports to improve signal integrity.

These materials are particularly suitable for high-speed optical modules such as 400G and 800G, providing a simple and efficient solution for thermal and EMI design in high-density layouts.

3. Material Selection and Synergistic Design

In the practical development of optical modules, the three materials are often used synergistically based on specific application scenarios:

- Thermal pads are selected for flat structures with high insulation requirements;

- Thermal gel is used for complex structures and tiny gaps;

- Thermally conductive absorbers are applied to areas with both heat generation and sensitivity to electromagnetic interference.

Through rational combination, it is possible to achieve efficient heat dissipation and EMI goals for optical modules while controlling costs.

4. Conclusion

The performance improvement of optical modules relies on advancements in thermal management and EMI suppression technologies. Thermal pads, thermal gel, and thermally conductive absorbers, as key functional materials, each have their focus while complementing one another. Selecting a supplier capable of providing complete material solutions and possessing extensive application experience is essential to ensuring the high performance and reliability of optical modules in a competitive market. We are committed to offering end-to-end services for optical module manufacturers, from material selection and prototyping to mass production support, driving optical communication technology toward higher speeds and greater density.