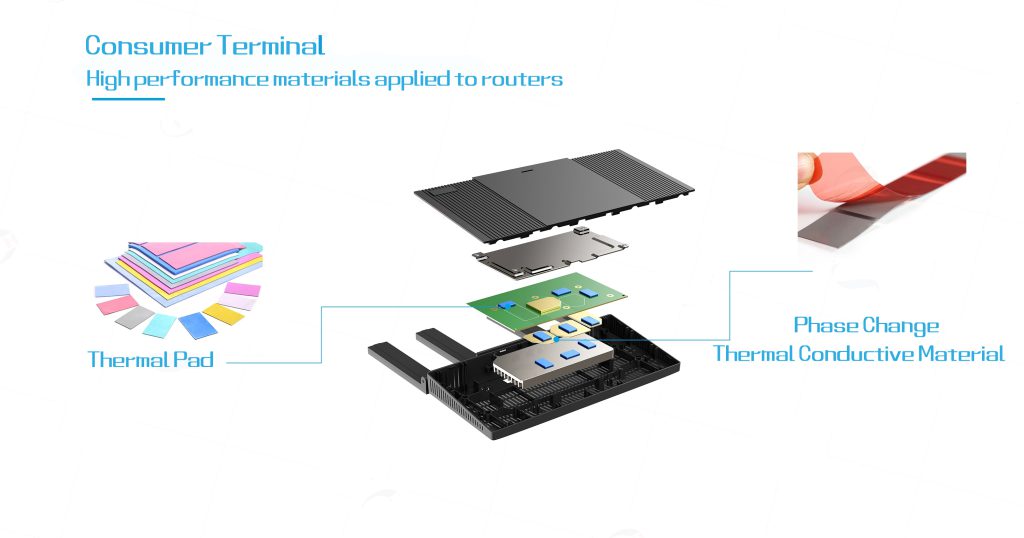

As network technology evolves toward higher speeds and greater functionality, modern routers face increasing thermal challenges that directly impact performance and reliability. This article examines how thermal pads and phase change materials provide effective thermal solutions for router applications.

Thermal Challenges in Router Design

Primary Heat Sources:

- Main processor and network processing units

- Power over Ethernet (PoE) controllers and power management ICs

- Wireless radio frequency components (Wi-Fi 6/6E/7)

- Network switch chips and PHY components

Critical Design Considerations:

- Limited internal space with high component density

- Passive or minimally-ventilated enclosure designs

- 24/7 continuous operation requirements

- Cost-sensitive manufacturing environment

Material Solutions for Router Thermal Management

Thermal Pads: Versatile Thermal Interface Solution

Application Areas:

Processor and Chipset Cooling:

- Between main processor and heatsink in mid-range routers

- For network switch chips requiring moderate thermal performance

- On power management components needing electrical isolation

RF and Wireless Module Applications:

- Wireless radio chipsets and power amplifiers

- RF front-end modules with consistent gap requirements

- Components requiring reliable insulation properties

Power Circuit Thermal Management:

- PoE controller circuits

- Voltage regulation modules

- Power supply interface components

Performance Advantages:

- Excellent balance of thermal performance and cost-effectiveness

- Simple installation process suitable for automated assembly

- Reliable electrical insulation characteristics

- Good compressibility and recovery for varying tolerances

Phase Change Materials: High-Performance Thermal Interface

Critical Applications:

High-Power Processor Interfaces:

- Between main CPU/GPU and primary heatsink in premium routers

- Applications requiring maximum thermal performance in minimal space

- Components with high thermal density and limited cooling capacity

Advanced Wireless Systems:

- High-power Wi-Fi 7 radio modules

- Multi-radio access points with thermal constraints

- 10Gbps+ network processors

Technical Benefits:

- Superior thermal performance compared to standard thermal pads

- Phase transition characteristics enabling optimal interface formation

- Minimal pump-out effect during thermal cycling

- Consistent long-term reliability under continuous operation

Implementation Strategies

Cost-Optimized Router Designs:

Thermal pads serve as the primary thermal interface material, providing reliable performance for most components while maintaining manufacturing efficiency and cost targets.

Performance-Oriented Router Designs:

Phase change materials are specified for critical heat-generating components, while thermal pads handle secondary thermal management requirements, creating an optimized thermal solution hierarchy.

Hybrid Implementation Approach:

- Phase change materials for primary processors and high-power RF components

- Thermal pads for secondary chipsets, power management, and support circuits

- Strategic material selection based on specific thermal requirements and cost considerations

Performance Considerations

Thermal Performance Metrics:

- Thermal conductivity requirements typically ranging from 1.5-6.0 W/m·K

- Interface thermal resistance optimization for specific component requirements

- Long-term stability under continuous operational temperatures

Reliability Requirements:

- Performance maintenance through thermal cycling (-40°C to 85°C)

- Material stability over 5-7 year product lifespan

- Resistance to drying, cracking, or performance degradation

Manufacturing Compatibility:

- Compatibility with automated assembly processes

- Rework capability for service and repair scenarios

- Shelf life and storage condition considerations

Conclusion

The strategic implementation of thermal pads and phase change materials enables router manufacturers to effectively balance thermal performance, reliability, and cost considerations. Thermal pads provide versatile, cost-effective solutions for broad application across router designs, while phase change materials deliver premium performance for the most thermally challenging components.

As router technology continues to advance with higher-speed networking standards and increased processing requirements, the thoughtful application of these thermal interface materials becomes increasingly critical. Manufacturers who successfully leverage both material technologies will deliver products that meet evolving performance demands while maintaining competitive positioning in the market.

The optimal thermal solution strategy involves careful analysis of specific router architecture, performance requirements, and cost targets to determine the most effective implementation of thermal pads and phase change materials for each application.