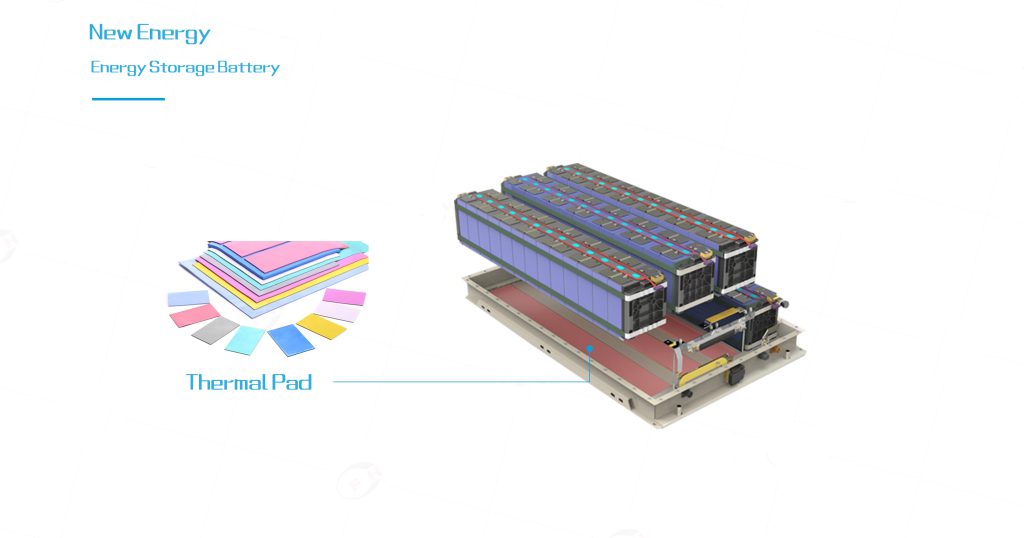

With the global transition toward renewable energy and electrification, energy storage systems (ESS) have become crucial components in smart grids, residential energy storage, and industrial power management. Among various ESS technologies, lithium-ion battery-based systems dominate the market due to their high energy density and efficiency. However, effective thermal management remains one of the most significant challenges in battery system design, directly impacting safety, performance, and lifespan. This article provides a comprehensive examination of thermal pads’ application in energy storage battery systems.

Thermal Challenges in Energy Storage Batteries

Heat Generation Mechanisms:

- Internal resistance heating during charge/discharge cycles

- Joule heating from high-current applications

- Chemical reaction heat during operation

- Environmental heat absorption in outdoor installations

Critical Temperature Considerations:

- Optimal operating range: 15°C to 35°C

- Performance degradation above 45°C

- Thermal runaway risk above 60°C

- Low-temperature performance limitations below 0°C

Safety Implications:

- Thermal runaway propagation between cells

- Accelerated aging at elevated temperatures

- Reduced efficiency and capacity loss

- Potential fire hazards in poorly managed systems

Thermal Pads: Fundamental Properties and Advantages

Material Characteristics:

- Thermal conductivity range: 1.0 to 6.0 W/m·K

- Compressibility: 10-30% deflection under typical pressure

- Dielectric strength: >5 kV/mm for electrical isolation

- Temperature resistance: -40°C to 150°C continuous operation

- Fire resistance: UL94 V-0 rated formulations available

Performance Benefits:

- Gap-filling capability for irregular surfaces

- Consistent performance under compression

- Long-term stability without pump-out or drying

- Vibration damping and mechanical stress absorption

- Easy installation and maintenance

Applications in Energy Storage Systems

Cell-to-Cell Thermal Interface:

- Between individual battery cells in modules

- Filling dimensional variations in cell spacing

- Providing electrical isolation between cells

- Facilitating heat transfer to cooling plates

Module-Level Applications:

- Between battery modules and thermal management systems

- Interface with liquid cooling plates or heat pipes

- Mounting surfaces for temperature sensors

- Isolation between modules at different potentials

System Integration:

- Busbar and electrical connection thermal management

- Power electronics thermal interface

- Battery management system (BMS) component cooling

- Enclosure-level thermal optimization

Design Considerations for Optimal Performance

Thermal Performance Factors:

- Thermal conductivity selection based on heat generation

- Thickness optimization for gap filling and pressure distribution

- Compression force requirements for interface efficiency

- Thermal impedance minimization strategies

Mechanical Considerations:

- Stack pressure calculation for battery cells

- Compression set characteristics for long-term performance

- Adhesive vs. non-adhesive installation options

- Reworkability for maintenance and repair

Safety and Compliance:

- Flame retardant requirements for different applications

- Toxicity and off-gassing considerations

- Environmental resistance (humidity, chemicals)

- Regulatory compliance (UL, IEC, UN standards)

Implementation Strategies

Large-Scale Commercial ESS:

- High-conductivity pads (3-6 W/m·K) for high-power applications

- Custom die-cutting for optimized material usage

- Automated installation processes for manufacturing efficiency

- Quality control protocols for consistent performance

Residential Energy Storage:

- Cost-optimized solutions with adequate performance

- Simplified installation for serviceability

- Safety-focused material selection

- Compact design integration

Industrial and UPS Applications:

- Robust designs for harsh environments

- Long-life formulations for critical applications

- High-reliability interfaces for mission-critical systems

- Maintenance-friendly configurations

Performance Validation and Testing

Thermal Performance Verification:

- Interface thermal resistance measurement

- Bulk thermal conductivity validation

- Temperature rise testing under operational loads

- Heat flux density capacity determination

Reliability Assessment:

- Thermal cycling performance (-40°C to 85°C)

- Compression set testing over time

- Aging characteristics under operational conditions

- Environmental stress testing

Safety Certification:

- Flame resistance testing per UL94

- Electrical isolation verification

- Material compatibility testing

- Toxic emission analysis

Case Studies and Performance Data

Commercial Scale ESS Installation:

- 2 MWh containerized system using 3.0 W/m·K thermal pads

- Maximum cell temperature reduction of 15°C compared to air gaps

- Temperature uniformity improvement of 60% across modules

- Projected lifespan increase from 10 to 15 years

Residential ESS Application:

- Wall-mounted system using 2.5 W/m·K silicone-based pads

- Consistent performance maintenance over 3-year operational period

- Zero thermal-related safety incidents

- Maintained 95% of original capacity after 2,000 cycles

Future Trends and Developments

Material Advancements:

- Higher conductivity formulations (8-15 W/m·K)

- Phase-change infused thermal pads

- Graphene-enhanced composite materials

- Sustainable and recyclable material options

Application Innovations:

- Integrated sensor technology

- Smart thermal interface materials

- Automated application systems

- Multi-functional materials combining thermal and structural properties

Industry Evolution:

- Standardization of thermal interface requirements

- Improved testing and validation methodologies

- Integration with digital twin technologies

- Advanced thermal modeling and prediction capabilities

Conclusion

Thermal pads play an indispensable role in modern energy storage battery systems, providing critical thermal management solutions that directly impact safety, performance, and longevity. The selection of appropriate thermal pad materials and designs requires careful consideration of thermal requirements, mechanical constraints, safety standards, and economic factors.

As energy storage systems continue to evolve toward higher densities, larger scales, and more demanding applications, the importance of advanced thermal interface materials will only increase. The ongoing development of thermal pad technologies promises to enable next-generation energy storage solutions that are safer, more efficient, and more reliable than current systems.

Manufacturers, system integrators, and end-users must recognize the critical nature of thermal management in battery systems and prioritize the selection and implementation of high-quality thermal interface solutions. Through continued innovation and careful application of thermal pads, the energy storage industry can overcome thermal challenges and accelerate the global transition to sustainable energy systems.